Most patients will never know the process to construct a building that is providing hope and a healing space. Patients do not know that before building starts there are government requirements that the health system must show a need for a new hospital. Most patients do not know that the construction of a large new hospital will include as many as three or four General Contractors, as many as 10 or 20 subcontractors and subcontractors to those subcontractors. All the patient knows is that they are there for healing and hope.

Most patients will never know the process to construct a building that is providing hope and a healing space. Patients do not know that before building starts there are government requirements that the health system must show a need for a new hospital. Most patients do not know that the construction of a large new hospital will include as many as three or four General Contractors, as many as 10 or 20 subcontractors and subcontractors to those subcontractors. All the patient knows is that they are there for healing and hope. Most patients will never know the process to construct a building that is providing hope and a healing space. Patients do not know that before building starts there are government requirements that the health system must show a need for a new hospital. Most patients do not know that the construction of a large new hospital will include as many as three or four General Contractors, as many as 10 or 20 subcontractors and subcontractors to those subcontractors. All the patient knows is that they are there for healing and hope.

Most patients will never know the process to construct a building that is providing hope and a healing space. Patients do not know that before building starts there are government requirements that the health system must show a need for a new hospital. Most patients do not know that the construction of a large new hospital will include as many as three or four General Contractors, as many as 10 or 20 subcontractors and subcontractors to those subcontractors. All the patient knows is that they are there for healing and hope.Installation of commercial construction projects is a tightrope act juggling logistics, dynamic schedules, site conditions and more.

At ASST, we have experienced Project Managers that understand what it means to successfully complete our projects on time. Our Project Managers always follow our process from contract agreement to completed installation. From large Divisions 6/12 new construction projects to medium renovation projects, our teams are always willing to Go Beyond for our customers.

At ASST, we have the capability to relieve the stress of managing surfaces, millwork and casework fabrication and installation. By adding Quartz surfaces to our line of services, we have become the nation’s premier fabricator of commercial surface products. Steve Stoddard is heading up our Quartz division. Steve has an award-winning resume of commercial surface experience and is the keystone of our Quartz foundation. ASST is your full package fabricator for Division 6 and Division 12 Healthcare, Education, Corporate/Public Space and Retail surfaces. Contact us today at info@asst.com or visit our website at www.asst.com.

At ASST, we are known for handling large capacity Division 6 and Division 12 projects. Many of our customers do not know that we are also known for custom solid surface projects. This video shows an example of our custom solid surface offerings.

At ASST, our first Core Value is BEYOND: Doing more than our competitors to assist our customers. ASST is uniquely positioned to fulfill all aspects of your casework, millwork, solid surface and quartz projects. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. We look forward to Going Beyond for your exciting project! Contact us today at info@asst.com or visit our website at www.asst.com.

We thought that we would share who we are, what we do and why we do it. Let us know how we can ASST you with your Division 6/12 commercial projects.

At ASST, our first Core Value is BEYOND: Doing more than our competitors to assist our customers. ASST is uniquely positioned to fulfill all aspects of your casework, millwork, solid surface and quartz projects. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. We look forward to Going Beyond for your exciting project! Contact us today at info@asst.com or visit our website at www.asst.com.

COVID-19 has changed our lives and it has changed commercial construction. Since March of 2020, we have all learned to adapt to the new world we live in. Commercial construction is one of the most dynamic environments to work in and with Covid-19, it has become even more challenging.

Social distancing, hand washing, wearing masks and health monitoring are some of the necessary requirements to reduce the risk of spreading Covid-19. When working in an already fluid environment, commitment to these health measures is of utmost importance.

At ASST (pronounced ə-ˈsist), we understand the importance of mitigating the risk of spreading Covid-19 as well as the importance of getting projects complete. On March 13 2020, our management teams went into action. We knew that this was big and we knew that we had to make immediate changes for the safety of our employees and our customers. On March 15, we had all of our offices disinfected by a professional service. On March 16, all office employees started working remotely and immediately after that, we added shifts to our fabrication facilities to promote social distancing. These are just a few of the measures that we have in place to protect our employees and our customers. We know that the world we live in is dynamic, just like the large commercial projects we successfully complete. Because of this, we are prepared to complete any Division 6/12 healthcare, education and corporate space project and do it safely.

At ASST, our first Core Value is BEYOND: Doing more than our competitors to assist our customers. ASST is uniquely positioned to fulfill all aspects of your casework, millwork, solid surface and quartz projects. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. We look forward to Going Beyond for your exciting project! Contact us today at info@asst.com or visit our website at www.asst.com.

In an aging world, our senior communities are no longer the last in line to receive the best in countertops. There are currently more than two million people living in some type of senior facility and this number will continue to grow. These communities require infection prevention as much as any community and the choice of countertops is paramount in reducing the spread of bacteria and viruses. Until recently, senior communities had to choose between bacterial resistant materials and aesthetically pleasing materials. Thanks to engineered materials, senior communities can now have the best of both worlds. Enter quartz countertops in senior living.

Many senior communities are requiring the same amenities that their communities had before retirement and some would even like an upgrade. While granite is a beautiful and durable material, there are some inherent problems with using it. The first and foremost problem with using granite in a senior community is that the material is porous. This requires a granite countertop to be continuously sealed to maintain any non-porous attributes. Another major problem with choosing granite for a senior community is consistency. Mother Nature is beautifully inconsistent and if you are aiming to maintain the same theme or color palette, a natural product will not work.

Quartz countertops are consistent in color/design and can have the look of granite. Quartz countertops are non-porous and never have to be resealed. This reduces the risks of infection and the amount of maintenance required. Our seniors deserve the best that retirement has to offer. This should include reducing the risk of infection and the feeling that a well-appointed home delivers.

At ASST, we have the capability to relieve the stress of managing surface, millwork and casework fabrication and installation. By adding Quartz surfaces to our line of services, we have become the nation’s premier fabricator of commercial surface products. Steve Stoddard is heading up our Quartz division. Steve has an award-winning resume of commercial surface experience and is the keystone of our Quartz foundation. ASST is your full package fabricator for Division 6 and Division 12 Healthcare, Education, Corporate/Public Space and Retail surfaces.

Commercial Construction is an extremely dynamic business. There are many moving parts and the only way to predict the outcome is to know every variable (Chaos Theory/Butterfly Effect). A manufacturer flaps their wings in China (can’t produce material) and a tornado happens in Texas (occupancy dates are pushed). This is akin to predicting the weather three weeks from today. The best you can do is prepare for multiple scenarios and make sure that you have the right trade partners.

Recently we were contacted by a customer who needed material fabricated for a job that another company had been contracted to fabricate. The company that had been contracted to fabricate this material was unable to produce in the timeframe required for occupancy of the project. ASST was asked if we could produce this needed product in an impossible time frame. Our team recognized an opportunity to highlight our ability to Go Beyond for our customer and we found a way to squeeze this into our backlog schedule. Could we do this every time? No, but we will always do our best to exceed the expectations of our customers.

At ASST our first Core Value is BEYOND: Doing more than our competitors to assist our customers. ASST is uniquely positioned to fulfill all aspects of your casework, millwork, solid surface and quartz project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. We look forward to Going Beyond for your exciting project! Contact us today at info@asst.com or visit our website at www.asst.com.

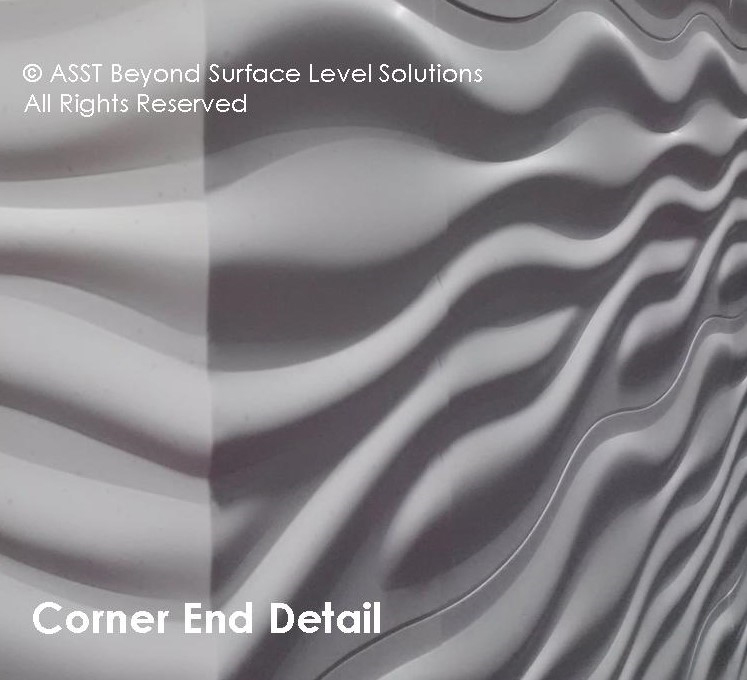

Solid surface thermoforming technologies allow for a myriad of complex forms to be created such as a topographic map. The lynchpin to creating extreme contours is 5 axis CNC machining. 3D CAD software such as SolidWorks ® can be utilized to model practically any surface texture. Designers are continuing to push the boundaries with innovative surfaces that enhance interior architectural space.

Many times design professionals submit drawings for bid to General Contractors without specifying an appropriate wall cladding product in the architectural specification. Designers run the risk of installing contoured vertical wall surfaces made from molded gypsum plaster or thin plastic. The costs required for maintenance of these ineffective wall cladding systems required an entire new approach.

In response, we focused our business around thermoforming from the beginning. ASST has created a truly “niche” business, catering to advanced fabrication solutions for commercial construction. We created SCULPTCOR ® textured wall cladding to provide a durable solution unlike anything on the market today. Manufactured with 100% solid surface acrylic, this is an bacterial resistant wall cladding that is made to last. ASST’s proprietary mounting system allows for field adjustment and individual panel removal for maintenance. It is ASST’s legacy to continue assisting design professionals with thermoforming project challenges other fabricators avoid. Contact us with your next solid surface project!

At ASST, we have be fabricating solid surfaces for 22 years. We have a solid surface fabrication facility in McSherrystown, PA and a quartz fabrication facility in Corry, PA. Whatever your needs, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Contact us now online or call us at 717-630-1251. WWW.ASST.COM

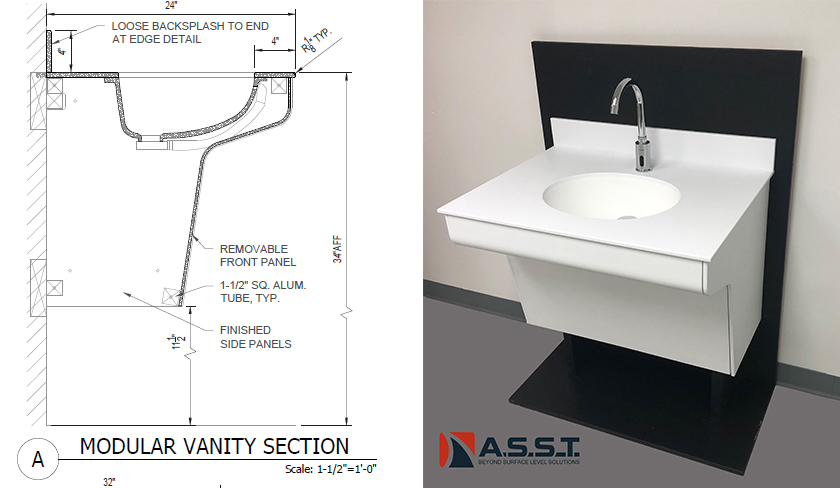

Designing restroom spaces that are both attractive and durable is a challenge. Properly designed public restroom facilities can enhance the experience for those who use and maintain their appearance. Restrooms in public spaces must meet the Americans with Disabilities Act Accessibility Guidelines (ADAAG). Studies have shown that proper design and planning reduces bacterial growth, queuing issues, and facility vandalism.

Traditional plastic laminate vanity countertops and drop-in sink bowls provide an opportunity for moisture to destroy a particleboard substrate. This creates an optimal environment for bacterial growth. We have all witnessed restroom countertops with laminate surfaces that have swelled from exposure to water.

To address this common problem, ASST developed a wall hung solid surface vanity system. The 30” wide modular units utilize a sturdy aluminum and polyethylene support structure with a removable solid surface front panel. The front panel is removable allowing for easy access to plumbing. The Modular Vanity system™ is available in 30” wide increments and includes a solid surface top, backsplashes, side panels, and your choice of an integral mounted sink. The system is available in all solid surface sheet products. Without wood that can rot and grow mold, the system is perfectly designed to handle rigorous public restroom environments.

At ASST, we have been fabricating solid surfaces for 22 years. We have a solid surface fabrication facility in McSherrystown, PA, and a quartz fabrication facility in Corry, PA. Whatever your needs, ASST can build it to the exact specifications, in a safe manner, and to the finest quality standards, you expect. Contact us now online or call us at 717-630-1251. WWW.ASST.COM

Is your Division 6 and Division 12 millwork, casework, solid surfaces and quartz trade partner ready for the new normal of commercial construction?

When commercial construction projects resume normal operations, some of your trade partners may not be ready for the new normal of the expectations of social distancing. Some of your trade partners may not even have made it through these difficult times. Do you know that your millwork, casework, solid surface and quartz trade partner will be ready when the flood gates open up? Is your Division 6 and Division 12 trade partner even still in business?

At ASST (ə-ˈsist), we expect that there will be a fast upswing in commercial project schedules as states are opened up to resume the new normal of commercial construction business operations. Because we are an essential business, we have already made the changes necessary to distance our employees and have even found a way to increase capacity while doing so. The safety of our employees and our customers is paramount in all the decisions we make. We are now looking at ways to monitor our social distancing practices within our ERP and our mobile devices. At ASST, we don’t forget the past and we are always looking to the future.

We are here to assist you with immediate, near future and distant future projects. ASST has been safely providing exceptional Division 6/12 millwork, casework, solid surfaces and quartz for 22 years. We have a solid surface fabrication facility in McSherrystown, PA and a quartz fabrication facility in Corry, PA. Whatever your needs, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Contact us now online, email us (info@asst.com) or call us at 717-630-1251. WWW.ASST.COM