The Construction Industry Institute reported that 55% of construction rework is caused by inaccurate documentation. This often happens when someone is referencing the wrong set of documents. It is critical to commercial construction project success to have one and only one set of documents that everyone is using. Utilizing or not utilizing centralized plans, photos, revision management and other important documents will make or break your projects.

Document accessibility on job sites is important. Equally important is having the correct documents while on site. What happens when changes are made due to site conditions and the Project Planner does not update the correct set of drawings? Rework.

Rework causes longer construction schedules that push occupancy dates and cost overruns that can be between 2%-20% of the project value. This percentage comes from the Construction Industry Institute of Texas. Could your project absorb a $400,000 rework on a $2,000,000 project? Rework not only affects your bottom line, but it can also cost companies their reputations and sway decisions regarding future work with a customer.

Throughout a project lifespan there will be multiple drawing revisions. Ensure that your document management system implements some type of version control. Some companies use in house developed document management systems. Some companies use out of the box software such as Procore, Textura, BIM 360, Plangrid and Blue Beam. These cloud based systems can assist with subcontractor communication. For example a millwork contractor gets the plumbing submittals that include sink cutouts and faucet information that is needed to fabricate the tops.

The bottom line is that if you do not have control of your documentation, you have a much lower chance of successfully completing your projects on time and in budget.

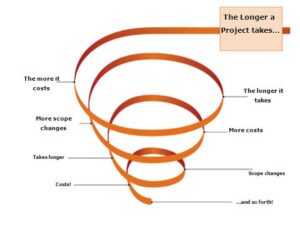

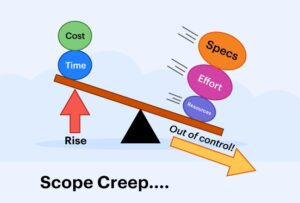

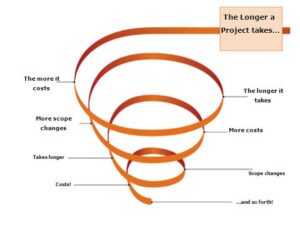

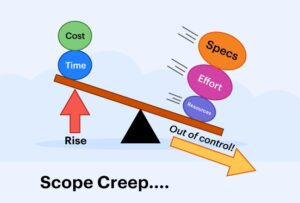

Commercial construction projects rarely progress exactly as planned. Wikipedia defines scope creep as changes, continuous or uncontrolled growth in a project’s scope, at any point after the project begins. This can occur when the scope of a project is not properly defined, documented, or controlled. It is generally considered harmful. Scope creep will happen when Project Managers fail to address changes as they occur. Failing to remain in control of project scope/schedule is a runaway train and will result in a financial train wreck.

What are some causes of scope creep? Poorly defined project scope. This usually begins with your preconstruction team. Failure to stick to change practices. If a customer asks you for a change, no matter how small, document it. Because one of our goals a satisfied customer, when asked for a change, we may agree without first initiating a change process. Any change in requirements, large or small, becomes a new feature (scope) that was not part of the original agreement.

Recently a large addition to the millwork scope was added to a healthcare project we were managing. This happened because the owner had overlooked it in the original design and therefore it was not part of the original contract. Our team immediately assessed how this would affect our responsibilities to complete this project on time and in budget. We did request additional material and labor cost to the added scope via a change order. In this case, we were ahead of schedule and did not have to work overtime to ensure that the work was completed on time. No overtime labor costs were passed on to our customer.

Another example is when a customer informs you that the owner would like the color of the solid surface countertops to be a complex patterned color that just so happens to be the most expensive group of coloring offered by the manufacturer. Your preconstruction team priced the material at a cost that is half that of what is now being requested. If your team did not clearly define what material was included in your proposal, you may be at odds with your customer about changing the scope/cost. This is a great example of scope creep that is caused by requirements or material not clearly defined.

There are many things you can do to help prevent scope creep. Make sure that your project is clearly defined. Something as simple as the color of countertops can make or break a project. Make sure that everyone on your team is aware that ALL changes to project scope are documented and go through the project management team. This includes employees that are handling submittals and installers. Let’s say that your submittal coordinator receives a phone call from the customer and they let them know what pulls they want on all of the casework and what company to use. The submittal coordinators thanks them for making their day just a little bit easier as they don’t need to dig through the specifications to find this information. They submit the pulls that were requested via the phone call not knowing that they are completely different from what is in the spec and costs 25% more. Your project costs just increased and no one even knows it. Another example is when your installers have a plan to go floor-by-floor installing tops. On a few floors, the trades before you are behind and the customer lets your site supervisor know that the schedule for installation has to be changed. If your site super does not let you know that you are delayed because of another trade you may be asked to keep your schedule. When this happens, it needs to be documented. Make sure that you have a clear process for dealing with changes. If there is no process then your team members have no guidelines for what has to be done with scope changes and will most likely assure scope creep. Make sure that changes are addressed immediately. It may become a problem if you go back to your customer with a change request for something that you have already completed.