Translucent materials are continuing to be highly popular with design professionals. Technological advances in LED lighting and CNC machining have been instrumental in this trend. Intricate patterns filled with liquid resin materials have many applications for both signage and artwork.

Translucent materials are continuing to be highly popular with design professionals. Technological advances in LED lighting and CNC machining have been instrumental in this trend. Intricate patterns filled with liquid resin materials have many applications for both signage and artwork.

Design professionals are frequently unaware of how to specify resin inlay work. As an innovative technique, fabricating resin inlays can be challenging to achieve satisfactory results. Project specifications many times do not adequately identify fabricators who have experience in this specialty area. Without credible experience, resin inlay projects can have disastrous results. Bubbling and cracking of resin are all potential outcomes for those without experience in this highly specialized area.

ASST’s team of technical experts are able to assist you with these complicated fabrications. With our experience, we have found that utilizing UV resistant resins that are self-leveling and non-yellowing are crucial to achieving a quality end result. We have experimented with many different products and can assist you with a solution that exceeds your expectations!

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

Sustainable and responsibly resourced materials are a requirement for most projects today. With LEED points a frequent requisite, the core materials specified need to be green. Design professionals have to comply with a variety of environmental requirements. Carbon emissions, regionally sourced materials and recycled content are all of foremost concern when specifying casework.

Sustainable and responsibly resourced materials are a requirement for most projects today. With LEED points a frequent requisite, the core materials specified need to be green. Design professionals have to comply with a variety of environmental requirements. Carbon emissions, regionally sourced materials and recycled content are all of foremost concern when specifying casework.

With a plethora of regulatory certifications required for wood products, it can be difficult to discern what information is most relevant. Some casework manufacturers are intentionally vague on the origins of their core materials to disguise their source. Design professionals today rarely have the time to investigate and confirm these materials with the certifications needed for a project.

In response to provide our customers with great service, ASST has developed a dealership alliance with TMI Systems to help with overcoming these challenges. TMI has been in business since 1969 and their trusted commitment to sustainable design is unmatched in the casework industry. Core material options are available with 20% recycled content as well as low emitting adhesives and composite woods. These are only a few of the benefits to this new dealership alliance. Combined with ASST’s industry leadership with solid surface fabrication, design professionals now have a comprehensive resource to obtain a CSI DIV 6 &12 specification solution. Whether it is for healthcare, education, corporate or retail our team can ASsiST you with your sustainable project goals. Who says it’s not easy being green?

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Even our EMR safety rating is outstanding at .793! We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

Healthcare interiors are seeing an increase in vertical solid surface. Owners, architects and designers alike are realizing the long term cost benefits of using solid surface vertically.

Healthcare interiors are seeing an increase in vertical solid surface. Owners, architects and designers alike are realizing the long term cost benefits of using solid surface vertically.

In the past, design professionals have had few choices for wall cladding in high traffic healthcare environments. Thin plastic wall protection systems or metal panels are not easily maintained and once damaged, need replacement. Healthcare wall cladding made of thin plastic sheets are neither antibacterial nor can withstand the abuse of multiple impacts from cart traffic. Everyone is familiar with seeing wall cladding damage throughout a healthcare facility. Costly maintenance of these wall cladding systems calls for a new approach. A better approach with a durable solid surface vertical solution that is inherently anti-bacterial to prevent the spread of infection.

To aesthetically as well as functionally address this problem, ASST created SCULPTCOR ® textured surfaces. Manufactured with 100% solid surface acrylic, this is an anti-bacterial wall cladding that is made to last. ASST developed the patented technology for texturing solid surface sheet materials. ASST’s proprietary mounting system allows for field adjustment and individual panel removal for maintenance. We invite you to contact us to discuss your next healthcare wall cladding project. Going Beyond for our customers is of prime importance!

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Even our EMR safety rating is outstanding at .793! We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

Today, solid surface materials are becoming utilized for more design applications than just countertops. New innovative core materials starting to find their place in solid surface fabrication. Design professionals are also fueling these changes with new applications such as doors with CNC routed designs to 1” thick solid surface toilet partitions.

Today, solid surface materials are becoming utilized for more design applications than just countertops. New innovative core materials starting to find their place in solid surface fabrication. Design professionals are also fueling these changes with new applications such as doors with CNC routed designs to 1” thick solid surface toilet partitions.

As design professionals explore these design applications for solid surface, technical challenges can arise. For example, solid surface panels for toilet partitions need to be lightweight but strong. Standard toilet partition hardware can’t handle the weight of a 1” thick solid surface acrylic partition. Additionally, cost implications of utilizing solid partitions can be difficult for any owner to accept.

ASST has a wealth of experience with arriving at innovative solutions for unique projects. For one corporate client, ASST proposed a fabrication solution for toilet partitions that preserved the design intent while satisfying owner concerns for performance. Honeycomb plastic core sheets are available in a variety of thicknesses. Most solid surface manufacturers now have sheet materials in thinner thicknesses from 1/4” to as thin as 1/8”. By creating a “sandwich” of 1/4” solid surface each side of a 1/2” thick core, the weight is drastically reduced. Standard partition hardware can now be utilized and any additional blocking or accommodation for toilet accessories can be made by the fabricator. Doing what ever it takes to solve a problem and Going Beyond for our customers is of prime importance. Our innovative team of estimators, planners and project managers collaborate and deliver project results in a way few competitors can.

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Even our EMR safety rating is outstanding at .793! We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

In construction, successful completion of a job is accomplished through effective project management. Delivering a quality project to your client on time and within budget while also turning a profit is no easy feat. It requires careful planning and detailed monitoring of project progress. Communication and collaboration with the General Contractor and other team members is of paramount importance.

In construction, successful completion of a job is accomplished through effective project management. Delivering a quality project to your client on time and within budget while also turning a profit is no easy feat. It requires careful planning and detailed monitoring of project progress. Communication and collaboration with the General Contractor and other team members is of paramount importance.

Detailed strategic planning is the most important aspect of successful construction project management. The more complex the project, the more planning will be required. A well-planned project maximizes efficiency and provides a step by step roadmap for completing the work on schedule and within budget. For example, college student housing projects can have very tight schedules. Students are scheduled to arrive back from summer break at a specific time. Delays and setbacks many times are not addressed quickly enough to hold the schedule by many solid surface subcontractors.

ASST has a wealth of project management experience in dealing with tight schedules for college student housing projects. For a recent project with Elizabethtown College, there were multiple delays on site that were slowing the job progress. In response, ASST’s Project Manager quickly mobilized the installation team to work longer days and weekends to meet the deadline. Doing what ever it takes and Going Beyond for our customers is of prime importance. Our innovative team of estimators, planners and project managers collaborate and deliver project results in a way few competitors can. Contact us today to see how we can make a difference on your next project!

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Even our EMR safety rating is outstanding at .793! We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

Solid surface is more traditionally utilized for countertops and interior vertical applications. In Europe and in Asia however, solid surface exterior wall panels and fixtures have been steadily gaining acceptance. Today, General Contractors and Architects in the United States are just beginning to discover the advantages of using solid surface for exterior applications.

Solid surface is more traditionally utilized for countertops and interior vertical applications. In Europe and in Asia however, solid surface exterior wall panels and fixtures have been steadily gaining acceptance. Today, General Contractors and Architects in the United States are just beginning to discover the advantages of using solid surface for exterior applications.

With any new architectural application, questions of durability become a concern. Concerns regarding lightfastness and thermal expansion require knowledgeable answers. Many fabrication shops in the United States have never used solid surface for exterior projects. Fabrication knowledge and experience are rare in this new “exterior territory” for solid surface.

To resolve these concerns, we have positioned our business to ASsiST customers with the technical challenges of an exterior project. Our depth of experience with exterior site furniture as well as exterior wall panels is invaluable as we work through the details to make your project happen. Our innovative team of estimators, planners and project managers collaborate and deliver project results in a way few competitors can.

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Even our EMR safety rating is outstanding at .793! We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

Assembling diverse subcontractor resources for design projects can be a challenge for both Design Professionals and the General Contractors. A reliable single subcontractor source that can coordinate a variety of specified finish materials for casework, solid surface and more under one contract.

Assembling diverse subcontractor resources for design projects can be a challenge for both Design Professionals and the General Contractors. A reliable single subcontractor source that can coordinate a variety of specified finish materials for casework, solid surface and more under one contract.

Both Architects and Designers and General Contractors need to work in concert to eliminate overlapping trades and define a clear scope of work with a minimum number of qualified subcontractors. The end goal is specifying superior low risk subcontractors that will combine Construction Specification Institute (CSI) Division scopes and build Owner value. Anything less will contribute to project scope confusion, miscommunication and costly change orders.

To address this issue, ASST has found value in providing a more comprehensive solution. A “one-stop” casework/millwork custom solution incorporating a wide variety of finish materials. ASST can perform work with wood veneers, plastic laminate, Trespa®, stone, metal, glass as well as all brands of solid surface and resin plastic materials. We believe the fit and finish of the final product is enhanced when building the internal framing structures ourselves. Our innovative team of estimators, planners and project managers collaborate and deliver project results in a way few competitors can.

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Our EMR safety rating is outstanding at .793! We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

Forming solid surface into complex geometric forms is still a relatively new topic to many design professionals. With advancing computer technologies, the future looks bright for those looking to push the boundaries of design with solid surface materials.

Forming solid surface into complex geometric forms is still a relatively new topic to many design professionals. With advancing computer technologies, the future looks bright for those looking to push the boundaries of design with solid surface materials.

Although thermoforming has been around awhile, advanced technologies to assist with fabrication has not. 5-axis CNC machining is an essential tool used in creating the molds necessary for thermoforming. Many fabrication businesses are focused on flat solid surface countertops and/or quartz. They may only have a small oven or vacuum table to form simple curves. The equipment costs and learning curve for thermoforming are out of reach for many of these fabrication businesses.

To address this issue, we focused our business from the beginning around thermoforming. ASST created a truly “niche” business, catering to advanced projects requiring fabrication solutions for commercial construction. ASST invested heavily in the necessary equipment and training required for thermoforming. ASST’s headquarters includes both offices and fabrication facilities, as well as a large thermoforming workshop. The workshop features three thermoforming ovens and two vacuum tables, as well as a 360-ton proprietary press and a vacuum press related to patented ASST technologies. It also has three CNC machines: one 5-axis CNC machine and two 3-axis CNC machines which allows us to reintroduce thermoformed parts to the 5-axis for final size machining. For cutting parts, ASST also has a Schelling panel saw. The shop is set up into typical “line work” areas for more common flat countertop fabrication work and has various open workshop areas for custom projects. Custom projects that frequently feature thermoformed solid surface parts. It is ASST’s legacy to continue assisting design professionals with thermoforming project challenges other fabricators avoid. Be sure to contact us with your next solid surface project!

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Our EMR safety rating is outstanding at .793! We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

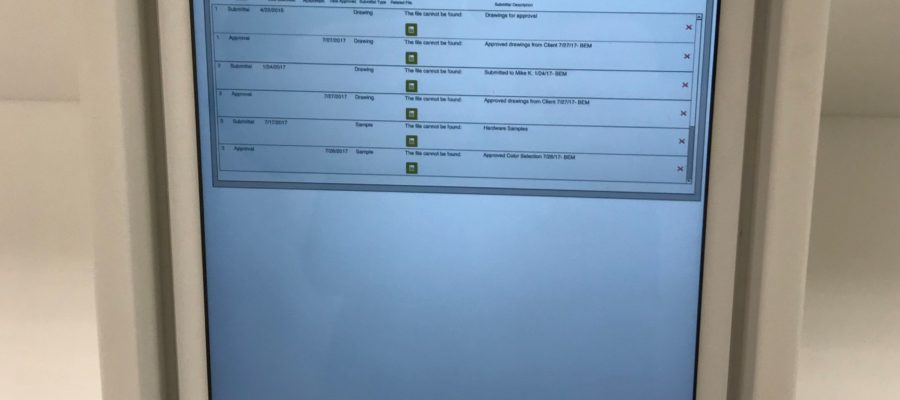

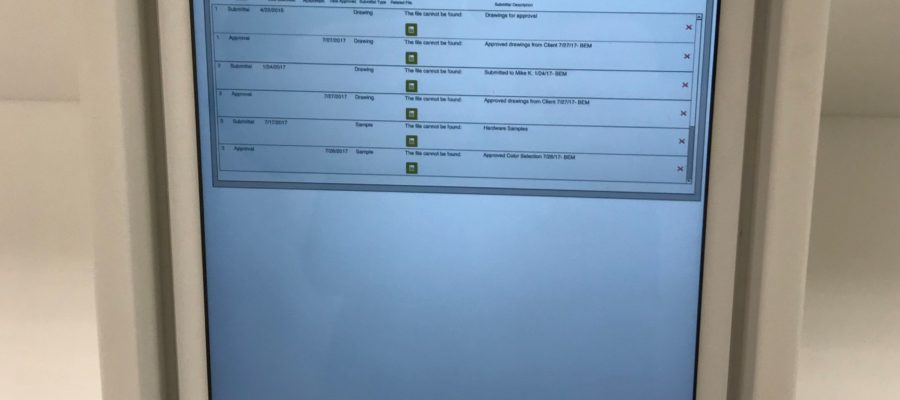

No one ever thought portable devices that would revolutionize a variety of industries so quickly. Organizational processes coupled with technologies to track projects and maintain schedules have become of paramount importance to an organization’s financial health.

The impact of iDevices have changed business in ways that those who have failed to adapt are in jeopardy of business failure. Innovation in processes are also important to keep work flowing smoothly through a fabrication facility. Unfortunately, constant deadlines preoccupy many fabrication business Owners from thoroughly examining their work flow. Developing a coherent system of transmitting accurate communications via portable devices is a necessity in today’s world. Costly errors are usually the result of poor communications which can add additional pressures to General Contractors who subcontract solid surface fabrications.

The impact of iDevices have changed business in ways that those who have failed to adapt are in jeopardy of business failure. Innovation in processes are also important to keep work flowing smoothly through a fabrication facility. Unfortunately, constant deadlines preoccupy many fabrication business Owners from thoroughly examining their work flow. Developing a coherent system of transmitting accurate communications via portable devices is a necessity in today’s world. Costly errors are usually the result of poor communications which can add additional pressures to General Contractors who subcontract solid surface fabrications.

To address this issue, ASST takes the organization and management of it’s projects very seriously. ASST’s Critical Operating Events and Tasks (COETS) for organizational process is one of the key benefits of working with us. From the beginning, your project is organized into 21 Event Steps from initial pricing to final onsite installation. The details of your project are properly planned and field verified, with shop drawings, prepared for approval prior to fabrication. Items for large millwork pieces are labeled and coded with field seaming joints and/or match lines indicated for the onsite installer. During production, your project is also checked for Quality Assurance to confirm that AWI standard are achieved. Portable iDevices are utilized to record production tasks conform to Architect’s specifications. These are just some of things we do to get a overhead view of your whole project. All of these 21 Event Steps are accessible via portable devices for use by project managers, installers and the fabrication team. We are always aware of the specific Event Step your project is presently located if you ever have a question!

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Even our EMR safety rating is outstanding at .793! We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

Just anyone can build casework right? Well, in a word no. At least not for healthcare and educational project applications. The quality has to be excellent and the service extraordinary. Rigorous requirements for LEED ® certification and FSC materials are further limiting the options available in the marketplace. General Contractors are also under pressure to bring to the table excellent casework subcontractors that prequalify well and limit risk to themselves and the Owner.

Just anyone can build casework right? Well, in a word no. At least not for healthcare and educational project applications. The quality has to be excellent and the service extraordinary. Rigorous requirements for LEED ® certification and FSC materials are further limiting the options available in the marketplace. General Contractors are also under pressure to bring to the table excellent casework subcontractors that prequalify well and limit risk to themselves and the Owner.

There are numerous ways of constructing casework but few can withstand the rigors of a healthcare or educational environment. Typical problems can include the use on non-moisture resistant MDF or particle board. Some fabricators do not follow AWI quality casework standards in their construction means and methods. They instead substitute with low cost materials and finishes that do not meet the Architect’s specification.

To address this issue, ASST has found value in providing a more proactive comprehensive solution. A “one stop” solid surface/ casework/millwork custom solution incorporating a wide variety of finish materials. ASST has now partnered with TMI Systems Corporation as a dealer for their line of casework. Based in North Dakota, TMI is a leader in quality casework fabrication. They are an excellent reputable resource and ASST looks forward to working with them on many future projects. With this new alliance, ASST can perform work with wood veneers, plastic laminate, Trespa®, stone, metal, glass as well as all brands of solid surface and resin plastic materials. Our innovative team of estimators, planners and project managers collaborate and deliver project results in a way few competitors can. We look forward to working with you on your next project!

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Even our EMR safety rating is outstanding at .793! We look forward to Going Beyond to address your exciting project challenges. Contact us now online or call us at 717-630-1251.

Translucent materials are continuing to be highly popular with design professionals. Technological advances in LED lighting and CNC machining have been instrumental in this trend. Intricate patterns filled with liquid resin materials have many applications for both signage and artwork.

Translucent materials are continuing to be highly popular with design professionals. Technological advances in LED lighting and CNC machining have been instrumental in this trend. Intricate patterns filled with liquid resin materials have many applications for both signage and artwork.

Sustainable and responsibly resourced materials are a requirement for most projects today. With LEED points a frequent requisite, the core materials specified need to be green. Design professionals have to comply with a variety of environmental requirements. Carbon emissions, regionally sourced materials and recycled content are all of foremost concern when specifying casework.

Sustainable and responsibly resourced materials are a requirement for most projects today. With LEED points a frequent requisite, the core materials specified need to be green. Design professionals have to comply with a variety of environmental requirements. Carbon emissions, regionally sourced materials and recycled content are all of foremost concern when specifying casework.

Healthcare interiors are seeing an increase in vertical solid surface. Owners, architects and designers alike are realizing the long term cost benefits of using solid surface vertically.

Healthcare interiors are seeing an increase in vertical solid surface. Owners, architects and designers alike are realizing the long term cost benefits of using solid surface vertically.

Today, solid surface materials are becoming utilized for more design applications than just countertops. New innovative core materials starting to find their place in solid surface fabrication. Design professionals are also fueling these changes with new applications such as doors with CNC routed designs to 1” thick solid surface toilet partitions.

Today, solid surface materials are becoming utilized for more design applications than just countertops. New innovative core materials starting to find their place in solid surface fabrication. Design professionals are also fueling these changes with new applications such as doors with CNC routed designs to 1” thick solid surface toilet partitions.

In construction, successful completion of a job is accomplished through effective project management. Delivering a quality project to your client on time and within budget while also turning a profit is no easy feat. It requires careful planning and detailed monitoring of project progress. Communication and collaboration with the General Contractor and other team members is of paramount importance.

In construction, successful completion of a job is accomplished through effective project management. Delivering a quality project to your client on time and within budget while also turning a profit is no easy feat. It requires careful planning and detailed monitoring of project progress. Communication and collaboration with the General Contractor and other team members is of paramount importance.

Solid surface is more traditionally utilized for countertops and interior vertical applications. In Europe and in Asia however, solid surface exterior wall panels and fixtures have been steadily gaining acceptance. Today, General Contractors and Architects in the United States are just beginning to discover the advantages of using solid surface for exterior applications.

Solid surface is more traditionally utilized for countertops and interior vertical applications. In Europe and in Asia however, solid surface exterior wall panels and fixtures have been steadily gaining acceptance. Today, General Contractors and Architects in the United States are just beginning to discover the advantages of using solid surface for exterior applications.

Assembling diverse subcontractor resources for design projects can be a challenge for both Design Professionals and the General Contractors. A reliable single subcontractor source that can coordinate a variety of specified finish materials for casework, solid surface and more under one contract.

Assembling diverse subcontractor resources for design projects can be a challenge for both Design Professionals and the General Contractors. A reliable single subcontractor source that can coordinate a variety of specified finish materials for casework, solid surface and more under one contract.

Forming solid surface into complex geometric forms is still a relatively new topic to many design professionals. With advancing computer technologies, the future looks bright for those looking to push the boundaries of design with solid surface materials.

Forming solid surface into complex geometric forms is still a relatively new topic to many design professionals. With advancing computer technologies, the future looks bright for those looking to push the boundaries of design with solid surface materials.

The impact of iDevices have changed business in ways that those who have failed to adapt are in jeopardy of business failure. Innovation in processes are also important to keep work flowing smoothly through a fabrication facility. Unfortunately, constant deadlines preoccupy many fabrication business Owners from thoroughly examining their work flow. Developing a coherent system of transmitting accurate communications via portable devices is a necessity in today’s world. Costly errors are usually the result of poor communications which can add additional pressures to General Contractors who subcontract solid surface fabrications.

The impact of iDevices have changed business in ways that those who have failed to adapt are in jeopardy of business failure. Innovation in processes are also important to keep work flowing smoothly through a fabrication facility. Unfortunately, constant deadlines preoccupy many fabrication business Owners from thoroughly examining their work flow. Developing a coherent system of transmitting accurate communications via portable devices is a necessity in today’s world. Costly errors are usually the result of poor communications which can add additional pressures to General Contractors who subcontract solid surface fabrications.

Just anyone can build casework right? Well, in a word no. At least not for healthcare and educational project applications. The quality has to be excellent and the service extraordinary. Rigorous requirements for LEED ® certification and FSC materials are further limiting the options available in the marketplace. General Contractors are also under pressure to bring to the table excellent casework subcontractors that prequalify well and limit risk to themselves and the Owner.

Just anyone can build casework right? Well, in a word no. At least not for healthcare and educational project applications. The quality has to be excellent and the service extraordinary. Rigorous requirements for LEED ® certification and FSC materials are further limiting the options available in the marketplace. General Contractors are also under pressure to bring to the table excellent casework subcontractors that prequalify well and limit risk to themselves and the Owner.