This unique Dupont Corian solid surface staircase was fabricated and installed for Nestle Corporation. The possibilities of solid surface are endless. At ASST we are going Beyond The Surface Level.

This unique Dupont Corian solid surface staircase was fabricated and installed for Nestle Corporation. The possibilities of solid surface are endless. At ASST we are going Beyond The Surface Level.

What is a flush mounted sink? A sink whereas the edge is flush with the top. There are different ways to mount a sink. Sinks can be top mounted, under mounted, or flush mounted. A sink that is glued or braced to the top of the counter creating an overlap is top mounted. This type of sink can be simply dropped in, glued and caulked. It can also be dropped in, fastened with hardware underneath and caulked. Under mounted sinks are glued under the counter or mounted with hardware. Flush mounted sinks are also glued under the counter. The counter is then cut down to fit the dimensions of the sink.

What is a flush mounted sink? A sink whereas the edge is flush with the top. There are different ways to mount a sink. Sinks can be top mounted, under mounted, or flush mounted. A sink that is glued or braced to the top of the counter creating an overlap is top mounted. This type of sink can be simply dropped in, glued and caulked. It can also be dropped in, fastened with hardware underneath and caulked. Under mounted sinks are glued under the counter or mounted with hardware. Flush mounted sinks are also glued under the counter. The counter is then cut down to fit the dimensions of the sink.

In all commercial environments reducing the risk of bacterial infection is essential. Mitigating the risk of bacterial infection is most essential in healthcare, education and laboratory environments. Since up to 80 percent of a bacterial cell’s weight is water, a sink is an ideal place for bacteria to propagate. Traditional top mount or bottom mount sinks leave a lip. This lip combined with moisture is a perfect environment for bacteria to lurk. Designing and building sink tops and bowls that promote bacterial growth can be a liability for the customer.

Flush mounted sinks are seamless, reducing the risk of bacterial growth, and aesthetically pleasing. The sink and top act as one continuous surface. This seamless design allows for a chic look and a healthy environment. ASST fabricates and installs these solid surface flush mounted sinks for commercial environments.

Call us today for your next commercial solid surface flush mounted sink project! Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the finest quality standards you expect. Contact us now online or call us at 717-630-1251.

Vanities are the fundamental piece of every bathroom. They not only are functional but create a style for the space. Solid surface vanity systems are the perfect combination of function and chic. Vanity systems can be made out of almost any solid surface material and used to create a practical layout for the space. Vanity Systems in public places face a considerable amount of use and abuse from the people using them. Vanity systems need to be pleasant to look at, but also serve their purpose as a tool.

Vanities are the fundamental piece of every bathroom. They not only are functional but create a style for the space. Solid surface vanity systems are the perfect combination of function and chic. Vanity systems can be made out of almost any solid surface material and used to create a practical layout for the space. Vanity Systems in public places face a considerable amount of use and abuse from the people using them. Vanity systems need to be pleasant to look at, but also serve their purpose as a tool.

Public Bathrooms are facing redesign. Standing in line while you have to use the restroom is a nuisance, and soon to be an issue of the past. As public restrooms expand to become more efficient and suitable for the volume of people using them, the need for a practical vanity systems increases. These systems are complex and need to be designed specifically for their space. How can public vanity systems be appealing, ADA compliant, easy to clean, and guaranteed to last a long time?

ASST is able to manufacture solid surface vanity systems that serve a variety of purposes in public buildings. Each ADA compliant vanity system made by ASST comes in a variety of size and colors. The designs are simple with no external fasteners which makes the vanity easy to clean. The solid surface material that ASST uses is bacteria and stain resistant. These durable vanities are made to last and easy to maintain.

Functionality is just as important as style. Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the finest quality standards you expect. Contact us now online or call us at 717-630-1251.

This Corian solid surface bench was designed by MIO Culture and fabricated by ASST. It is located in downtown Philadelphia.

At ASST we are going Beyond the Surface Level.

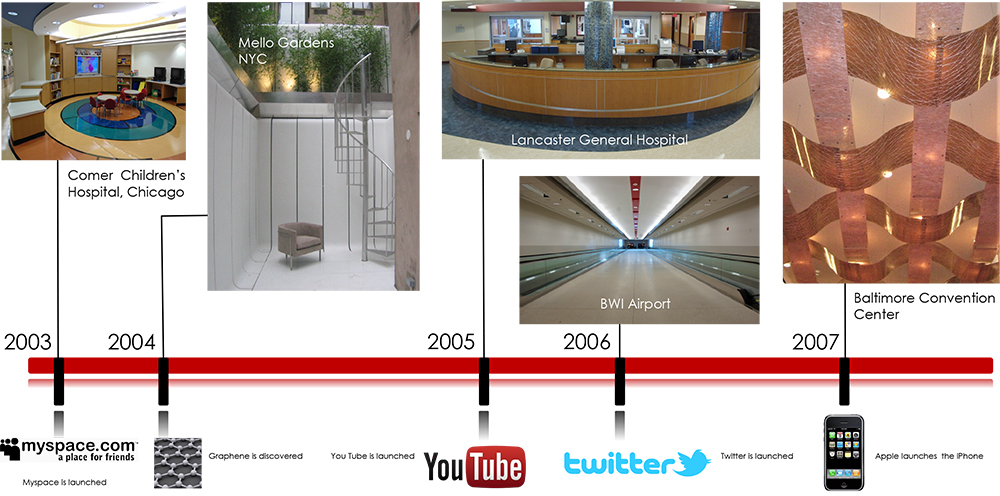

The period of 2003 to 2007 witnessed many positive changes for ASST. Larger more impressive projects with higher profile clients brought growth to ASST. Our reputation for taking on project challenges others avoid was solidified by some of the important milestone projects mentioned below.

We look forward to Going Beyond™ for the next twenty!

Over the next three months we will be rewinding the past with some highlights of our history to date. Below are the second five years:

We all know solid surface is both durable and repairable. Do we know what this man-made surfacing material is made of? Solid surface was invented in 1967 and patented in 1968 by DuPont. They formally introduced the Corian® brand to the public in 1971 at a trade show in Houston. It was first promoted as a kitchen and bath countertop material. Solid surface is made of a blend of acrylic, epoxy or polyester resins and alumina trihydrate (ATH). This mixture is poured onto a moving belt and cured in an oven. Both pigment and aggregate add-ins can be mixed into the sheet to create an infinite variety of color and textural effects.

We all know solid surface is both durable and repairable. Do we know what this man-made surfacing material is made of? Solid surface was invented in 1967 and patented in 1968 by DuPont. They formally introduced the Corian® brand to the public in 1971 at a trade show in Houston. It was first promoted as a kitchen and bath countertop material. Solid surface is made of a blend of acrylic, epoxy or polyester resins and alumina trihydrate (ATH). This mixture is poured onto a moving belt and cured in an oven. Both pigment and aggregate add-ins can be mixed into the sheet to create an infinite variety of color and textural effects.

With the expiration of DuPont’s patent, a plethora of new manufacturers have introduced competing brands. This has pushed the evolution of solid surface beyond countertops to more vertical and complex architectural applications. All solid surfaces are cast polymers. Some utilize special formulations to create enhanced transparency or artistic effects to differentiate their products in the marketplace. Brand confusion has many design professionals being uncertain of performance characteristics for various brands in the marketplace. This uncertainty can reduce innovation and expansion into additional architectural applications.

In response, ASST has primarily focused on propelling fabrication technology. We believe providing design professionals with unbiased valuable case study information regarding our experiences to be valuable to the design community. We work in concert with ALL brands to provide fabrication solutions to assist with project challenges other fabricators avoid.

First impressions always count! Be sure to call us for your next solid surface project! Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the quality standards you expect. Contact us now online or call us at 717-630-1251.

Durability and beauty are unlikely partners. It is rare when both are exclusive when specifying vertical surfaces. Even rarer still is the challenge for design professionals to use solid surface textures in a variety of vertical applications. From elevator cab interiors to wall protection, finding unique surfacing solutions can be a challenge. Many of these wall finishes are designed for residential use only and will not perform well in commercial spaces. With solid surface the design opportunities are endless.

Durability and beauty are unlikely partners. It is rare when both are exclusive when specifying vertical surfaces. Even rarer still is the challenge for design professionals to use solid surface textures in a variety of vertical applications. From elevator cab interiors to wall protection, finding unique surfacing solutions can be a challenge. Many of these wall finishes are designed for residential use only and will not perform well in commercial spaces. With solid surface the design opportunities are endless.

Public spaces demand durable surfaces. High performance surfaces should not be plain or unattractive. They should perform beautifully. Many vertical surfacing solutions in the marketplace today are focused only on aesthetics. Performance is usually an afterthought. Few surfacing products today combine both aesthetics and durability in one vertical solution. Solid surface can be thermoformed with textured patterns and CNC machined in a variety of custom patterns. Painted MDF or molded plaster can not offer the same value.

In response, ASST created SCULPTCOR ® textured wall surfaces to provide an attractive durable solution unlike anything on the market today. Manufactured with 100% solid surface acrylic, this is an antibacterial wall cladding that is made to last. ASST’s proprietary mounting system allows for field adjustment and individual panel removal for maintenance. It is ASST’s legacy to continue assisting design professionals with project challenges other fabricators avoid. Be sure to contact us with your next solid surface project!

First impressions always count! Be sure to call us for your next SCULPTCOR® project! Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the quality standards you expect. Contact us now online or call us at 717-630-1251.

Solid surface thermoforming technologies allow for a myriad of complex forms to be created such as a topographic map. The linchpin to creating extreme contours is 5 axis CNC machining. 3D CAD software such as SolidWorks ® can be utilized to model practically any surface texture. Designers are continuing to push the boundaries with innovative surfaces that enhance interior architectural space.

Solid surface thermoforming technologies allow for a myriad of complex forms to be created such as a topographic map. The linchpin to creating extreme contours is 5 axis CNC machining. 3D CAD software such as SolidWorks ® can be utilized to model practically any surface texture. Designers are continuing to push the boundaries with innovative surfaces that enhance interior architectural space.

Many times design professionals submit drawings for bid to General Contractors without specifying an appropriate wall cladding product in the architectural specification. Designers run the risk of installing contoured vertical wall surfaces made from molded gypsum plaster or thin plastic. The costs required for maintenance of these ineffective wall cladding systems required an entire new approach.

In response, we focused our business around thermoforming from the beginning. ASST has created a truly “niche” business, catering to advanced fabrication solutions for commercial construction. We created SCULPTCOR ® textured wall cladding to provide a durable solution unlike anything on the market today. Manufactured with 100% solid surface acrylic, this is an anti-bacterial wall cladding that is made to last. ASST’s proprietary mounting system allows for field adjustment and individual panel removal for maintenance. It is ASST’s legacy to continue assisting design professionals with thermoforming project challenges other fabricators avoid. Be sure to contact us with your next solid surface project!

First impressions always count! Be sure to call us for your next SCULPTCOR project! Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the quality standards you expect. Contact us now online or call us at 717-630-1251.

Specifying a reliable resource for healthcare casework is of prime importance. With everyone in the construction industry being stretched, specifying the right casework system that adheres to project specifications is critical. From sustainable construction and solid surface materials to acquiring LEED points, the pressure is on to specify the right choice for end users.

Specifying a reliable resource for healthcare casework is of prime importance. With everyone in the construction industry being stretched, specifying the right casework system that adheres to project specifications is critical. From sustainable construction and solid surface materials to acquiring LEED points, the pressure is on to specify the right choice for end users.

It is difficult to sort through the variety of options for healthcare casework brands in the marketplace today. Few manufacturers provide the transparency to allow an “apples to apples” comparison of product. This creates confusion in the marketplace and presents challenges to specifiers and contractors who want to recommend the right product for an end user. This market confusion has necessitated the creation of extensive casework mockup evaluations for projects adding additional time for evaluating potential casework product.

To minimize the above issues and provide a more comprehensive solution, ASST has now partnered with TMI Systems as a dealer for their line of healthcare casework. Based in North Dakota, TMI is a leader in high quality laminate modular casework fabrication. Their sustainable modular casework products feature railmounted overhead cabinets and forward-thinking reconfigurable base cabinets. With Autodesk 3D BIM software, design professionals are able to thoroughly document planning decisions in drawings used in the approval process. With cutting edge computer 3D renderings, end users can understand the proposed designs even better. With the new ASST/TMI alliance, design professionals are providing solutions that can truly evolve with end user needs.

Let us assist you with your next healthcare casework project! Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the quality standards you expect. Contact us now online or call us at 717-630-1251.

This desk is being fabricated using a laminate base, Corian solid surface top, aluminum stand offs with 3Form decorative blinds.

At ASST we are Going Beyond the Surface Level.