In the jobs market today, finding and retaining good employees can be a challenge. The Society for Human Resource Management reported that on average it costs a company 6 to 9 months of an employee’s salary to replace an employee. So if an employee makes $75,000 per year it will cost the company $37,500-$56,250 in recruiting and training. We all know that your employees are the face of your company, they are the people that make your products, they are the people that manage your projects, and they are the glue that holds your ship together. There are many things your company can do such as competitive salaries, benefits, etc. Below are a few things you can do, that really don’t cost much, to retain your productive employees.

Make sure that you show appreciation for good work with positive reinforcement. Sometimes a simple “nice job” or “thank you” can go a long way. Employees want to know that Going Beyond is recognized. If you have employees that manufacture a product, share with them the end result of their work. For example, if you manufacture millwork for hospitals, show employees completed pictures of the hospital. Let them know that because of their hard work, a place for healing has been created. If you build schools, let your employees know that because of their hard work our future leaders have a place to learn and grow.

The US Chamber of Congress list “Allowing employees to speak their minds” as one of the most important methods of retaining employees. It is important for employees to feel that their opinions about the business are being heard by management. Make sure that employees have a method to share their opinions with management. Make sure that you address all suggestions no matter how silly they might sound. If your employee Bobbi suggests that everyone gets a new car you could respond by saying “Hey Bobbi, this isn’t the Oprah show… you get a car… you get a car… but we are providing lunch for everyone at the employee safety meeting on Friday”. If you have an employee that makes a suggestion, that helps with efficiency, and that suggestion is implemented, acknowledge the recommendation in front of that person’s peers.

Happiness is infectious and happy employees are more productive than disgruntle employees. Forbes recently cited a study by Camille Preston that happy employees are up to 20% more productive and with sales people that number increases to 37%. A simple smile when passing someone can have a profound effect in how that person feels. Start meetings with a piece of good news. This can set the tone for your meeting. Make happy part of your company culture.

Encourage a work life balance. If you are in a manufacturing or labor intensive industry give your employees flexible start/stop times. Let your employees know that you understand that they have a life outside of work and you want to promote a healthy balance.

At ASST, we know that productive employees need more than continued employment. Our employees are the face of our company and they really are the glue that holds our ship together. Our employees fabricate and install your best work!!

Solid surface is one of the most versatile millwork finishes. There are some guidelines when specifying solid surfaces to keep your design intent. Below are a few of those guidelines.

Seams

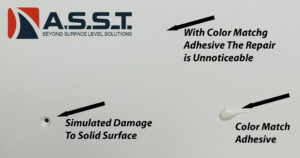

Solid colors and colors with small particulates will either show no seam at all (solid colors) or be difficult to see (small particulates). Solid surfaces colors that will show a seam are any color that has movement (swirls, large particulates, etc.). Keep in mind that most solid surfaces come in 30” X 144”. If your project has a surface area larger than this, there will be a seam. The last thing you want is your best work to have, what might be considered, a flaw that is painfully obvious. If you have any reservations about how a seam will look, contact your fabricator and ask them to send you large seamed samples. Any good fabricator will do this at no cost to your firm.

Color and Finish Level

Solid surfaces come in hundreds of colors from different manufacturers. While solid surface is a versatile surface with few limitations, there are some guidelines when specifying light and dark colors. When you are choosing color selection for a working surface (transaction ledges, tops, etc.) stay away from dark colors. Dark colors will show every little scratch and although they are easy to repair, it will have to be done often to keep the aesthetic you have designed. Light colors don’t show scratches easily and most often will only require basic cleaning. Dark solid surfaces are great for vertical applications such as die walls or wall cladding. When specifying a dark color, make sure that you specify the finish level. A matte finish on a black solid surface will actually look grey. With very dark colors you will want at least a semi-gloss finish. Keep in mind that the higher the finish the higher the cost as there is more labor involved.

Thermoforming

Thermoforming solid surfaces gives you the ability to remove the chains and take your design to a whole new level. Solid surfaces are no longer just the flat countertop in a well-appointed kitchen. Thermoformed solid surfaces can be used for anything from an eye-catching nurse’s station to the radius corners in an operating room and beyond. When specifying a thermoformed solid surface project, make sure that you specify the fabricator of choice. Don’t let your best work be doled out to the cheapest millworker.

At ASST, we have been fabricating healthcare solid surfaces for 23 years. We have a solid surface fabrication facility in McSherrystown, PA and a quartz fabrication facility in Corry, PA. Whatever your needs, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Contact us online or call us at 717-630-1251. WWW.ASST.COM

Inova Loudon Hospital

What does it take to successfully manage the millwork package for a $200M+ healthcare project? There is no single ingredient that defines a successful large millwork project. The overall process has to be complete and well-defined. From initial contract to project completion, there are many steps in between. These steps will define whether the project is successful or not.

Hershey Children’s Hospital

Have you ever received a submittal and asked yourself “is this company looking at the right specifications”? Have you ever received shop drawings and wondered “do these people even know what an AWI standard is”? Every General Contractor has been in a situation where they have received shop drawings for approval and the casework is on the wrong side of a wall or something similar.

Reading Hospital

On every large project, the schedule is one of the most difficult things to control for a project manager. It can be difficult to fabricate when the time between field measuring and installation is compressed. When this is not planned correctly other trades can get pushed as well as occupancy deadlines. What happens when your millworker cannot meet the deadline for completed installation?

United Therapeutics

At ASST, our process for success is well-defined and is continuously reviewed. We have a team of Submittal Coordinators that will push to get approvals back in a timely manner. Our Project Planners have the right tools for field measuring and handle site verification. They handle machine programming and fabrication scheduling. Our Project Managers have decades of experience and the ability to handle dynamic environments. Our shops are set up to handle the most unique custom projects as well as very large high capacity projects. All of our employees have the tenacity to be successful.

Did you know that it costs between $400 and $700 per square foot to build a hospital depending on the geographic location (Becker’s Hospital Review)? For example, in Los Vegas the cost to build a hospital is between $285 and $455 per square foot. While in New York City the cost is between $475 and $700 per square foot. When a health network spends this kind of money they want to make sure that it will be done on time and in budget. An operating room costs the health system around $2,200 per hour for direct and indirect cost (American Journal of Managed Care). Hospitals charge between $3200 per hour and $10,000 per hour per operating room (Journal of Clinical Anesthesia, Stanford). The sooner the health system can take occupancy the sooner they can start recouping that investment.

Did you know that it costs between $400 and $700 per square foot to build a hospital depending on the geographic location (Becker’s Hospital Review)? For example, in Los Vegas the cost to build a hospital is between $285 and $455 per square foot. While in New York City the cost is between $475 and $700 per square foot. When a health network spends this kind of money they want to make sure that it will be done on time and in budget. An operating room costs the health system around $2,200 per hour for direct and indirect cost (American Journal of Managed Care). Hospitals charge between $3200 per hour and $10,000 per hour per operating room (Journal of Clinical Anesthesia, Stanford). The sooner the health system can take occupancy the sooner they can start recouping that investment.

One of the most important decisions that General Contractors and Owners can make is the selection of subcontractors. What happens when the subcontractor does not have the capacity to complete the project in the schedule required? Usually the General Contractor will have to hustle to find another subcontractor to supplement the work that cannot be completed by the awarded sub. This is painful and a deduct change order ensues or worse the performance bond is engaged and a replacement subcontractor has to be contracted. After this the GC usually will have to explain why schedule is not going to be met to the owner.

One of the most important decisions that General Contractors and Owners can make is the selection of subcontractors. What happens when the subcontractor does not have the capacity to complete the project in the schedule required? Usually the General Contractor will have to hustle to find another subcontractor to supplement the work that cannot be completed by the awarded sub. This is painful and a deduct change order ensues or worse the performance bond is engaged and a replacement subcontractor has to be contracted. After this the GC usually will have to explain why schedule is not going to be met to the owner.

Some of the questions that have to be answered for any successful General Contractor and owner are as follows: Does this subcontractor have experience with this type of work? Does this subcontractor have the capacity to handle this type of work? Does this subcontractor operate safely? Does this subcontractor provide the quality of work to meet and exceed the expectations of the owner? Is this subcontractor financially sound? If the answers to ALL of these questions are not a resounding YES then your project is at risk.

Some of the questions that have to be answered for any successful General Contractor and owner are as follows: Does this subcontractor have experience with this type of work? Does this subcontractor have the capacity to handle this type of work? Does this subcontractor operate safely? Does this subcontractor provide the quality of work to meet and exceed the expectations of the owner? Is this subcontractor financially sound? If the answers to ALL of these questions are not a resounding YES then your project is at risk.

At ASST, we have been successfully providing millwork, casework and solid surfaces on large health care projects for 23 years. We have the capacity for large projects, the processes to keep schedule, we do it safely, we are financially sound and we have the Project Managers that know how to be successful. We look forward to Going Beyond for your exciting project! Contact us today at 717-630-1251/ info@asst.com or visit our website at www.asst.com.

At ASST, we have been successfully providing millwork, casework and solid surfaces on large health care projects for 23 years. We have the capacity for large projects, the processes to keep schedule, we do it safely, we are financially sound and we have the Project Managers that know how to be successful. We look forward to Going Beyond for your exciting project! Contact us today at 717-630-1251/ info@asst.com or visit our website at www.asst.com.

What is templating? Templating is defining of a shape in relation to the site conditions compared to the building plans. Why do we template? Templating a project is important to reduce field (re)work and provide a product that can be installed with minimum modifications. How do we template? There are different ways to template commercial construction scope. One way is to use an angle finder and a tape measure. Some companies might even create a template with cardboard from the measurements done by a person. While this tried and true method has been used for generations, there is room for human error. Another method is digital templating. There are many different digital templating tools on the market. Digital templating helps to mitigate human error but requires the tools to be calibrated. Uncalibrated tools can be just as disastrous as writing down a measurement incorrectly. When do we template? Templating is done when all other trades before us have completed their work. If templating is done before other trades are completed, site conditions can change and templates could be rendered useless.

(Using a digital templating tool helps reduce the amount of human error)

(Using a digital templating tool helps reduce the amount of human error)What could go wrong? When templating is not done correctly, oftentimes it is not noticed until installation. Some materials can be easily repaired in the field such as solid surface. Other materials, such as quartz or granite, simply cannot be repaired in the field. In the case of a large project, by the time installation is happening the fabricator may have already produced a large portion of the scope of work. In this case, the product may have to be re fabricated. This could cause project delays and even occupancy delays.

What could go right? When templating is done properly, field modifications are eliminated or reduced. This means that countertops can be dropped in placed reducing time and ensuring project success.

At ASST, we use two different digital templating tools. We make sure that our tools are calibrated, we take digital pictures and we verify with manual measurements. We understand that the devil is in the details.

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications you require and the finest quality standards you expect. Contact us today at 717-630-1251/info@asst.com or visit our website at www.asst.com

At ASST we are overjoyed to have participated in a project that is sure to bring smiles to children and their families during a time of illness. Our team worked tirelessly to bring this project to fruition, on time and in budget. If you take the time to view this video you will see how our processes work and meet some of the team members that were willing to Go Beyond to provide a healing space for children.

At ASST, we have been providing Division 6 and Division 12 millwork, casework, solid surfaces and quartz for large healthcare projects for 22 years. We understand that to become a beacon of hope for an entire community, the healing space must be innovative and constructed with the highest standards. We have the experience to provide project scope on time, in budget and we do it safely. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards, you expect. We look forward to Going Beyond for your exciting project! Contact us today at info@asst.com or visit our website at www.asst.com.

There are millworkers and countertop fabricators struggling to prosper in almost every city. Most fabricators can make a top to exact field measurements without issue and it is easy to find casework that will measure up to your project. There are many choices for Division 6 & Division 12 Millwork, Casework, Solid Surface and Quartz fabricators. Finding a vendor or subcontractor is not a difficult task. Finding a millwork, casework, solid surfaces and quartz partner that can take your project Beyond the Surface Level is another story.

What if you are designing or building a large health system and you need a partner that can handle the solid surfaces, quartz, millwork and casework. Some of the solid surfaces are unique and thermoformed and some of the solid surfaces are flat tops. The thermoformed surfaces are patterned and you need to know what the seams will look like. You need 575 of them. The millwork and casework have different requirements depending on the department and quartz is going in all of the executive offices. For this type of project, you need a partner with years of experience and the capacity to handle this volume of work. Do you know who you will call on to assist with your high-profile project?

At ASST (ə-ˈsist) we have been fabricating and installing Division 6/Division 12 Millwork, Casework, Solid Surfaces and Quartz for 22 years. We have successfully completed a large portfolio of health systems, schools and public space projects and we have received numerous awards for innovation and craftmanship. We know that if there is particulate in a solid surface it may not bend well; how tight a radius bend can be with some solid surface materials and we know that certain colors of solid surface material do not seam well. Many laboratories, pharmacies and critical care operations are now requiring organic-free material in their furnishings and we are now offering our Welnest Furnishings which have no organic material (www.welnest.com).

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. We look forward to Going Beyond for your exciting project! Contact us today at 717-630-1251 or visit our website at www.asst.com.

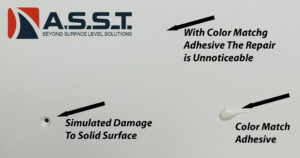

Newborns are in a “primary curve” C-shaped fetal position upon birth and for the first few months of life, they do not yet have the muscles to support their head. Research has shown that keeping an infant’s spine straight is not a sound physiological position and in addition to stressing the baby’s spine, it can also negatively influence the development of the baby’s hip joints (Dr. Evelin Kirkilionis, University of Freiburg).

Straightening the baby’s spine immediately after birth is not healthy. Giving birth is stressful for the mother and healthcare providers have made advancements in reducing this stress for mothers. If you do a web search for reducing the stress of child birth you will find most results are geared toward reducing the stress for mothers.

At ASST, we know that reducing the stress of birth for the child is important to every parent and the desire for every parent is to have a happy, healthy baby. We worked with the labor and delivery team at St. Joseph Medical Center in Baltimore to develop our Cradle Baby Bathing Bowl®. Our Cradle Baby Bathing Bowl® is ergonomically designed to support the newborn and reduce the risk of Healthcare Acquired Infection. From Africa to Australia, our Cradle Baby Bathing Bowl® is part of new life around the world.

Whatever your solid surface needs, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Contact us now online or call us at 717-630-1251.

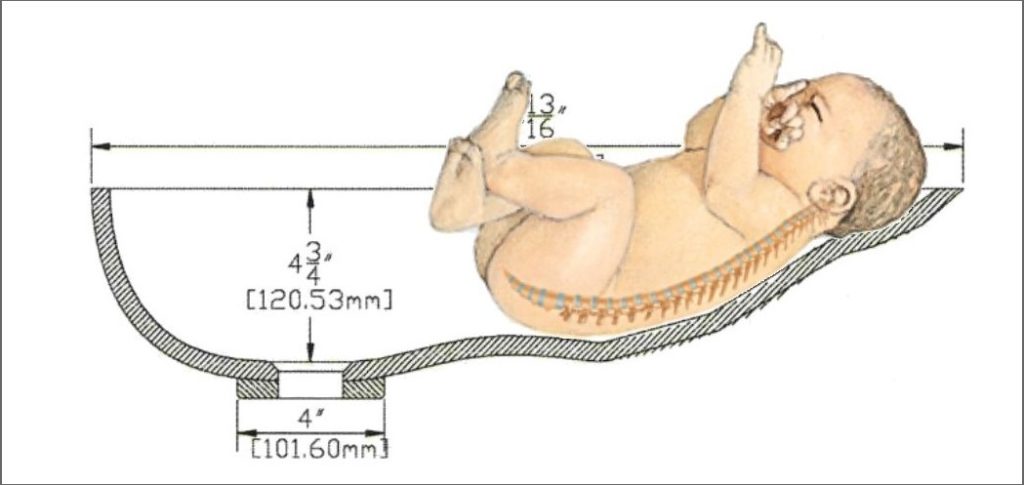

Healthcare Acquired Infections are also known as nosocomial (nōzōˈkōmēəl) infections. The awareness of Healthcare Acquired Infections (HAI) is at an all-time high and prevention or reduction of HAI is crucial to caring for the patient. HAI costs are incurred by the patient and the healthcare provider. Patient costs of HAI include increased length of stay and even death. Healthcare provider costs of HAI are withheld provider compensation and higher insurance rates.

How can healthcare providers reduce the risk of HAI? One of the primary methods of reducing HAI, according the Centers for Disease Control and Prevention, is environmental cleaning. How can you clean a laminated top with a chip exposing the particle board core? The answer is that you can’t. In most healthcare environments, once a PLAM countertop has been chipped, it will have to be replaced to ensure that the healthcare provider is reducing the risk of HAI and will pass a healthcare inspection.

What if your method of infection control cleaning damages your furnishings? Ethanol, bleach and strong detergents will deteriorate Plastic Laminate (PLAM) exposing the particle wood substrate beneath. This provides a medium for bacteria to grow and another check mark for the health inspector. When PVC edge banding peals, the exposed wood substrate is a prime location for bacterial growth as well.

Solid Surfaces are resistant to chemicals, restistant to bacteria and will not delaminate. This makes solid surfaces desirable for healthcare environments and HAI can be reduced by replacing PLAM with solid surfaces. Every health system should make the replacement of laminate surfaces with solid surfaces part of their Infection Control Plan.

At ASST, we have been fabricating healthcare solid surfaces for 22 years. We have a solid surface fabrication facility in McSherrystown, PA and a quartz fabrication facility in Corry, PA. Whatever your needs, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Contact us now online or call us at 717-630-1251.