Most patients will never know the process to construct a building that is providing hope and a healing space. Patients do not know that before building starts there are government requirements that the health system must show a need for a new hospital. Most patients do not know that the construction of a large new hospital will include as many as three or four General Contractors, as many as 10 or 20 subcontractors and subcontractors to those subcontractors. All the patient knows is that they are there for healing and hope.

Most patients will never know the process to construct a building that is providing hope and a healing space. Patients do not know that before building starts there are government requirements that the health system must show a need for a new hospital. Most patients do not know that the construction of a large new hospital will include as many as three or four General Contractors, as many as 10 or 20 subcontractors and subcontractors to those subcontractors. All the patient knows is that they are there for healing and hope.Installation of commercial construction projects is a tightrope act juggling logistics, dynamic schedules, site conditions and more.

At ASST, we have experienced Project Managers that understand what it means to successfully complete our projects on time. Our Project Managers always follow our process from contract agreement to completed installation. From large Divisions 6/12 new construction projects to medium renovation projects, our teams are always willing to Go Beyond for our customers.

At ASST, we have the capability to relieve the stress of managing surfaces, millwork and casework fabrication and installation. By adding Quartz surfaces to our line of services, we have become the nation’s premier fabricator of commercial surface products. Steve Stoddard is heading up our Quartz division. Steve has an award-winning resume of commercial surface experience and is the keystone of our Quartz foundation. ASST is your full package fabricator for Division 6 and Division 12 Healthcare, Education, Corporate/Public Space and Retail surfaces. Contact us today at info@asst.com or visit our website at www.asst.com.

At ASST, we are known for handling large capacity Division 6 and Division 12 projects. Many of our customers do not know that we are also known for custom solid surface projects. This video shows an example of our custom solid surface offerings.

At ASST, our first Core Value is BEYOND: Doing more than our competitors to assist our customers. ASST is uniquely positioned to fulfill all aspects of your casework, millwork, solid surface and quartz projects. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. We look forward to Going Beyond for your exciting project! Contact us today at info@asst.com or visit our website at www.asst.com.

We thought that we would share who we are, what we do and why we do it. Let us know how we can ASST you with your Division 6/12 commercial projects.

At ASST, our first Core Value is BEYOND: Doing more than our competitors to assist our customers. ASST is uniquely positioned to fulfill all aspects of your casework, millwork, solid surface and quartz projects. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. We look forward to Going Beyond for your exciting project! Contact us today at info@asst.com or visit our website at www.asst.com.

In an aging world, our senior communities are no longer the last in line to receive the best in countertops. There are currently more than two million people living in some type of senior facility and this number will continue to grow. These communities require infection prevention as much as any community and the choice of countertops is paramount in reducing the spread of bacteria and viruses. Until recently, senior communities had to choose between bacterial resistant materials and aesthetically pleasing materials. Thanks to engineered materials, senior communities can now have the best of both worlds. Enter quartz countertops in senior living.

Many senior communities are requiring the same amenities that their communities had before retirement and some would even like an upgrade. While granite is a beautiful and durable material, there are some inherent problems with using it. The first and foremost problem with using granite in a senior community is that the material is porous. This requires a granite countertop to be continuously sealed to maintain any non-porous attributes. Another major problem with choosing granite for a senior community is consistency. Mother Nature is beautifully inconsistent and if you are aiming to maintain the same theme or color palette, a natural product will not work.

Quartz countertops are consistent in color/design and can have the look of granite. Quartz countertops are non-porous and never have to be resealed. This reduces the risks of infection and the amount of maintenance required. Our seniors deserve the best that retirement has to offer. This should include reducing the risk of infection and the feeling that a well-appointed home delivers.

At ASST, we have the capability to relieve the stress of managing surface, millwork and casework fabrication and installation. By adding Quartz surfaces to our line of services, we have become the nation’s premier fabricator of commercial surface products. Steve Stoddard is heading up our Quartz division. Steve has an award-winning resume of commercial surface experience and is the keystone of our Quartz foundation. ASST is your full package fabricator for Division 6 and Division 12 Healthcare, Education, Corporate/Public Space and Retail surfaces.

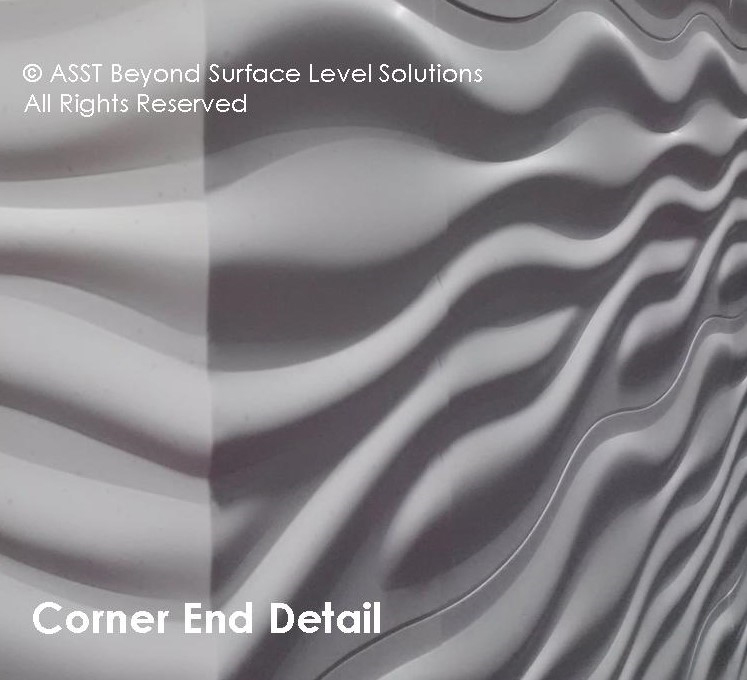

Solid surface thermoforming technologies allow for a myriad of complex forms to be created such as a topographic map. The lynchpin to creating extreme contours is 5 axis CNC machining. 3D CAD software such as SolidWorks ® can be utilized to model practically any surface texture. Designers are continuing to push the boundaries with innovative surfaces that enhance interior architectural space.

Many times design professionals submit drawings for bid to General Contractors without specifying an appropriate wall cladding product in the architectural specification. Designers run the risk of installing contoured vertical wall surfaces made from molded gypsum plaster or thin plastic. The costs required for maintenance of these ineffective wall cladding systems required an entire new approach.

In response, we focused our business around thermoforming from the beginning. ASST has created a truly “niche” business, catering to advanced fabrication solutions for commercial construction. We created SCULPTCOR ® textured wall cladding to provide a durable solution unlike anything on the market today. Manufactured with 100% solid surface acrylic, this is an bacterial resistant wall cladding that is made to last. ASST’s proprietary mounting system allows for field adjustment and individual panel removal for maintenance. It is ASST’s legacy to continue assisting design professionals with thermoforming project challenges other fabricators avoid. Contact us with your next solid surface project!

At ASST, we have be fabricating solid surfaces for 22 years. We have a solid surface fabrication facility in McSherrystown, PA and a quartz fabrication facility in Corry, PA. Whatever your needs, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. Contact us now online or call us at 717-630-1251. WWW.ASST.COM

Quartz has been popular in residential kitchens and bathrooms. Now we are seeing a surge in quartz specifications in commercial construction. Why? Quartz is heavy and expensive right? Yes, and no. Quartz may be heavy but it is very durable. Quartz is actually engineered stone. When compared to the total cost of natural stone, quartz engineered stone is less expensive.

How is quartz engineered stone actually “engineered”? No, manufacturers don’t recreate magma under the same conditions as volcanic activity created by the earth’s crust. Quartz engineered stone is made with ground quartz, other natural materials and resins. Natural quartz and other materials are ground into a dust or aggregate. The natural materials are mixed with resins and even glass to provide unique colors. Once the material is mixed it is baked at high temperature and the final step is polishing. OK we probably oversimplified the process.

One of the benefits of quartz engineered stone is the look of natural stone with quartz being much more consistent. Imagine having to find consistent natural stone slabs for 100 tops in a commercial building. Owners and designers don’t have to worry about whether or not the stone tops will match the rest of the building design and quartz tops don’t have to compete with the rest of the esthetics. Quartz engineered stone can be the focal point or complementary to the overall look and feel of the surrounding space.

Is quartz engineered stone a green construction material? Simply put yes. No natural stone is quarried for the purpose of producing quartz engineered stone. All of the natural material used in engineered quartz are byproducts of other manufacturing processes. Even the resins used in manufacturing quartz are becoming more bio friendly. These facts with the consideration of the amount of energy required transport natural stone from the quarries makes quartz engineered stone the right solution for commercial stone tops.

Here are some quartz engineered stone facts: Quartz is harder than granite making it resistant to impact damage. Quartz is non-porous which makes it resistant to bacteria, stain resistant, easy to clean and low maintenance. Quartz is made of 90-95 percent natural stone and 5-10 percent polymer resins. Quartz material does not have to be sealed.

At ASST, our quartz facility is dedicated to quartz alone. At this facility, we do one thing and we do it well. Steve Stoddard was the 2015 ISFA fabricator of the year and he leads our quartz offering. Contact ASST to find out how we can take your quartz engineered stone project Beyond the Surface Level.

Public seating in high traffic applications can take quite a beating. Design professionals are under increasing pressure from clients to provide seating solutions that are both durable and comfortable. Many are unaware of the flexibility solid surface provides to create seating that conforms ergonomically. The inherent performance characteristics of thermoformed solid surface materials provide an amazing opportunity to increase the longevity of public seating.

Design professionals today are bombarded with a plethora of furniture seating solutions. Unfortunately, many of these “seating systems” are poorly manufactured with planned obsolescence. Constructed of cheaper plastics, many of these systems fail soon after warranty expiration. This is hardly a strategy for clients looking to be environmentally responsible. Design professionals need to provide smart ergonomic seating solutions addressing both performance and value. These challenges seem insurmountable when industry standard public seating systems don’t fulfill your specified requirements.

ASST has the capability to help. With a state-of-the-art thermoforming studio, we can create ergonomic seating to your exact design specifications. We can share past solid surface project case studies to inspire your creativity. Working in concert with your team, we provide design assistance and credible information to present to your clients. Tailored services to meet busy design professional’s needs are what we do!

Assembling diverse subcontractor resources for design projects can be a challenge for both Design Professionals and General Contractors. A reliable single subcontractor source that can coordinate a variety of specified finish materials for casework, solid surface and more under one contract is difficult to find.

Both Architects and Designers and General Contractors need to work in concert to eliminate overlapping trades and define a clear scope of work with a minimum number of qualified subcontractors. The end goal is specifying superior low-risk subcontractors that will combine the Construction Specification Institute (CSI) Division scopes and build Owner value. Anything less will contribute to project scope confusion, miscommunication and costly change orders.

To address this issue, ASST has found value in providing a more comprehensive solution. A “one-stop” casework/millwork custom solution incorporating a wide variety of finish materials. ASST can perform work with wood veneers, plastic laminate, stone, metal, glass as well as all brands of solid surface, quartz, and resin plastic materials. We believe the fit and finish of the final product is enhanced when building the internal framing structures ourselves. Our innovative team of estimators, planners and project managers collaborate and deliver project results in a way few competitors can.

ASST is uniquely positioned to fulfill all aspects of your project. Whatever you need, ASST can build it to the exact specifications, in a safe manner and to the finest quality standards you expect. We look forward to Going Beyond to address your exciting project challenges. Contact us today at 717-630-1251 or visit our website at www.asst.com.