What can be specified as solid surface? Columns, staircases, wall cladding, cabinets? Yes, yes, yes, and yes. Everyone knows that solid surface is a great material for countertops. The non-porous nature of solid surfaces makes this material great for countertops in healthcare, schools, kitchens and public spaces. Many people do not know that solid surfaces can be used in other applications as well. Below are some examples:

Columns. Columns are the structural elements that transfer loads from the slab to the foundation. Many architects and designers are realizing that instead of trying to hide columns they can be aesthetically pleasing by making necessary columns a focal point. This can be accomplished by adding solid surface cladding to the columns. Because there are so many color combinations for solid surface you can design the space for any experience. While dark colors are not the best option for working surfaces, the vertical non-working surfaces of columns can be done in any color. Keep in mind when specifying solid surface clad columns that each manufacturer requires expansion joints. Instead of trying to hide the expansion joints it is best to add a reveal as part of the design. Another important technical element to cladding columns is knowing the radius of the column in comparison to how tight the radius can be of the material you are specifying.

Staircases. Staircases provide access to different floors and the roof of a building. Many of us remember thinking of a staircase or stairwell as a means of travel between floors when the elevator was not working. Or maybe an egress in the case of a fire. Concrete treads, block walls andan area of a building that often was not cleaned regularly used to defined a stairwell. But things have changed. Today many of us are choosing to take the stairs in an effort to maintain a healthy lifestyle and a means to achieve our 10,000 steps daily. Owners are recognizing this and providing stairwells and staircases that provide a more positive space for the occupants. Solid surface clad staircases can provide a clean and uplifting experience while traversing floor to floor. Add backlighting to a solid surface staircase and you have provided safety and a better user experience. Keep in mind that when using solid surfaces in staircases often times the cladding will have a compound thermoform. Make sure that you specify your fabricator of choice that has the technical knowledge to achieve your design intent.

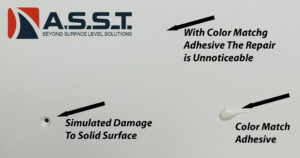

Wall Cladding. Solid surface used as wall cladding is damage resistant and easily repaired. The non-porous nature of solid surfaces make solid surface wall cladding an ideal material for public spaces, labs, kitchens and even operating rooms. Solid surface wall cladding does not have to be boring. You can choose Sculptcor™ wall cladding to provide texture while retaining the clean ability of a solid surface wall. Solid surface flat wall panels are easy to install and will outlast most of the surrounding materials.

Cabinets. Solid surface cabinets are popular in Europe and are becoming the standard in the United States for certain environments. Wood substrate cabinets simply cannot handle the harsh environments of a healthcare emergency room without chipping and de-laminating. This exposes the wood substrate and is a great place for bacteria to grow. Because solid surfaces are not laminated and non-porous, there is no place for bacteria to hide and can be easily cleaned. Solid surface cabinets are impervious to moisture, resistant to damage and heat, and can be repaired easily. We placed a wood substrate cabinet and one of our solid surface cabinets on the roof of our offices leaving them there for almost three years. Both cabinets are AWI rated “Institutional”. After one year the wood substrate cabinet had swelled and completely de-laminated to the point that it could not be moved without completely falling apart. Our solid surface cabinet experienced a broken hinge because of the wind whipping the door open and was easily repaired. Otherwise the solid surface cabinet is in good working order. Even the slow close slides still work like new. When specifying solid surface cabinet understand that the upfront cost of specifying solid surface over traditional cabinet can be more but the TCO is much less.