A considerable part of fabricating with solid surface is adhering separate pieces together. The solid surface fabrication joint requires a strong bond while maintaining aesthetics. This is accomplished by using the right solid surface adhesive that is matched to the surface color. The solid surface adhesive can be stronger than the material itself and with color matching, it is possible for the joint to subsist unnoticed.

A considerable part of fabricating with solid surface is adhering separate pieces together. The solid surface fabrication joint requires a strong bond while maintaining aesthetics. This is accomplished by using the right solid surface adhesive that is matched to the surface color. The solid surface adhesive can be stronger than the material itself and with color matching, it is possible for the joint to subsist unnoticed.

Solid surfaces such as Corian©, Avonite©, Krion©, LG HI-MACS©, etcetera require adhesive to be joined together. Incorrectly joined solid surface can be unappealing and even dangerous. In most cases, designers and architects do not want seams that are visible for their projects. In all cases designers, architects and contractors want solid surfaces that will not come apart. Imagine someone leaning against a solid surface top and it coming apart. No one wants a product that could injure a customer.

Each manufacturer of solid surface makes adhesive that is color matching and ASST uses the correct color matching adhesive for each project. ASST has 20 years of solid surface fabrication experience. We know what adhesives to use, the correct amount to use and the correct way to finish the adhesive.

If you want your next project to stick in the minds of your customers, let ASST help you out. Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the quality standards you expect. Contact us now online or call us at 717-630-1251.

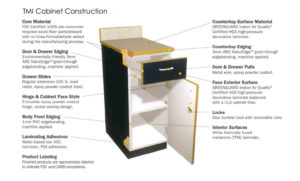

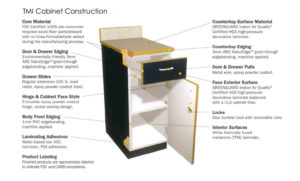

With the environment continuing to be a focus in the news, design professionals are required by end users to specify materials that are environmentally friendly. Carbon emissions generated from building products are a tremendous challenge for manufacturers across the globe. Specifying casework fabricated with woodbased products that are not only recycled, but also contribute to a lower carbon footprint is the end goal.

With the environment continuing to be a focus in the news, design professionals are required by end users to specify materials that are environmentally friendly. Carbon emissions generated from building products are a tremendous challenge for manufacturers across the globe. Specifying casework fabricated with woodbased products that are not only recycled, but also contribute to a lower carbon footprint is the end goal.

Many casework manufacturers utilize formaldehyde wood fiber particleboard for casework construction. These manufacturers tend to “downplay” their material construction in favor of a better price point. Laminates are usually not Greenguard certified and may contribute to off gassing. Specifying casework products without the proper green project credentials will likely prevent opportunities for LEED participation towards the fulfillment of point requirements.

To minimize the above issues, ASST has now partnered with TMI Systems as a dealer for their line of casework. Based in North Dakota, TMI is a leader in high quality plastic laminate modular casework fabrication. Their commitment to sustainability is impressive. With Single Chain of Custody certification from the Rainforest Alliance, TMI can provide a sustainable casework solution. Their modular casework products feature railmounted overhead cabinets and forward-thinking reconfigurable base cabinets. With Autodesk 3D BIM software, design professionals are able to more thoroughly document planning decisions in drawings used in the approval process. With cutting edge computer 3D renderings, end users can understand the proposed designs even better. With the new TMI/ASST alliance, design professionals are providing solutions that can truly evolve with end user needs.

Let us assist you with your next casework project! Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the quality standards you expect. Contact us now online or call us at 717-630-1251.

How do you design and shape solid surface projects? The technique of thermoforming is used to mold and shape different solid surface materials. This allows flat sheets of synthetic solid surface material to be transformed into almost any shape. By using heat and pressure the synthetic material is shaped into different three dimensional, rounded designs. The material is heated until it is pliable, placed over a mold and vacuum formed by removing the air between the material and a high temperature silicon membrane. Once the material has cooled it is trimmed to exact specifications using our 5 axis CNC.

How do you design and shape solid surface projects? The technique of thermoforming is used to mold and shape different solid surface materials. This allows flat sheets of synthetic solid surface material to be transformed into almost any shape. By using heat and pressure the synthetic material is shaped into different three dimensional, rounded designs. The material is heated until it is pliable, placed over a mold and vacuum formed by removing the air between the material and a high temperature silicon membrane. Once the material has cooled it is trimmed to exact specifications using our 5 axis CNC.

Not all surfaces can be molded and turned into three dimensional shapes but most synthetic solid surfaces can. This process cannot be used on other solid surface materials like quartz and granite. Companies that choose synthetic solid surfaces have a broader range of artistic ability when it comes to solid surface projects. Thermoforming is a tricky trade and creating the right balance of heat and bend is crucial to this process. The different chemical makeup of synthetic solid surfaces requires different temperatures. There are also limitations of the bend radius with different materials. No one enjoys telling a customer that the project has to be redesigned because the material specified cannot be formed into the desired shape.

ASST has thermoformed most synthetic solid surfaces and we know the requirements for each. With the high level of technology in our fabrication facility, there are no limitations to the design of synthetic solid surfaces. ASST can bend synthetic surfaces any which way to bring your 2D project plans into to the 3D world.

Let ASST bend over backwards for you on your next project. Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the finest quality standards you expect. Contact us now online or call us at 717-630-1251.

United Therapeutics

SOLID SURFACE IS REACHING NEW HEIGHTS. These Corian® and 3Form® walls were fabricated for United Therapeutics.

At ASST we are going Beyond the Surface Level™. CONTACT US TODAY FOR YOUR NEXT VERTICAL SOLID SURFACE PROJECT.

How do you get the ‘WOW’ factor across in your next solid surface project? Backlighting. Solid surface designs can be extraordinary and lighting them up can make them stand out from the rest. Backlighting acts like the cherry on top to the solid surface sundae and is a perfect finishing touch. The right type of lighting will make the architecture attract attention, illuminate details, and add dimension to the project.

How do you get the ‘WOW’ factor across in your next solid surface project? Backlighting. Solid surface designs can be extraordinary and lighting them up can make them stand out from the rest. Backlighting acts like the cherry on top to the solid surface sundae and is a perfect finishing touch. The right type of lighting will make the architecture attract attention, illuminate details, and add dimension to the project.

Composition and depth of the solid surface can get lost in dark locations. Some of the leading solid surfaces on the market today have an element of translucency. The last thing anyone would want would be for that trait of translucency to go unnoticed. Don’t let your solid surface project fade into the background. Make it the centerpiece by lighting it up.

At ASST we create the most breathtaking and eye catching designs of Corian®, 3Form®, Krion®, LG HiMacs®, Avonite®, as well as other solid surface materials. Our creations come in different textures, colors, transparencies, and backlighting will make them stand out even more. Lighting fixtures can range from LED panels to light tape. Either way, lighting behind an ASST solid surface will make your project radiate in its space. ASST can design and incorporate backlighting into the solid surface project plan to make sure that it is unique and enhances the solid surface.

Let ASST guide you through the dark on your next solid surface backlighting project. Whatever you need, ASST can build it to your exact specifications, in a safe manner, and to the finest quality standards you expect. Contact us now online or call us at 717-630-1251.

A considerable part of fabricating with solid surface is adhering separate pieces together. The solid surface fabrication joint requires a strong bond while maintaining aesthetics. This is accomplished by using the right solid surface adhesive that is matched to the surface color. The solid surface adhesive can be stronger than the material itself and with color matching, it is possible for the joint to subsist unnoticed.

A considerable part of fabricating with solid surface is adhering separate pieces together. The solid surface fabrication joint requires a strong bond while maintaining aesthetics. This is accomplished by using the right solid surface adhesive that is matched to the surface color. The solid surface adhesive can be stronger than the material itself and with color matching, it is possible for the joint to subsist unnoticed.

With the environment continuing to be a focus in the news, design professionals are required by end users to specify materials that are environmentally friendly. Carbon emissions generated from building products are a tremendous challenge for manufacturers across the globe. Specifying casework fabricated with woodbased products that are not only recycled, but also contribute to a lower carbon footprint is the end goal.

With the environment continuing to be a focus in the news, design professionals are required by end users to specify materials that are environmentally friendly. Carbon emissions generated from building products are a tremendous challenge for manufacturers across the globe. Specifying casework fabricated with woodbased products that are not only recycled, but also contribute to a lower carbon footprint is the end goal.

How do you design and shape solid surface projects? The technique of thermoforming is used to mold and shape different solid surface materials. This allows flat sheets of synthetic solid surface material to be transformed into almost any shape. By using heat and pressure the synthetic material is shaped into different three dimensional, rounded designs. The material is heated until it is pliable, placed over a mold and vacuum formed by removing the air between the material and a high temperature silicon membrane. Once the material has cooled it is trimmed to exact specifications using our 5 axis CNC.

How do you design and shape solid surface projects? The technique of thermoforming is used to mold and shape different solid surface materials. This allows flat sheets of synthetic solid surface material to be transformed into almost any shape. By using heat and pressure the synthetic material is shaped into different three dimensional, rounded designs. The material is heated until it is pliable, placed over a mold and vacuum formed by removing the air between the material and a high temperature silicon membrane. Once the material has cooled it is trimmed to exact specifications using our 5 axis CNC.

How do you get the ‘WOW’ factor across in your next solid surface project? Backlighting. Solid surface designs can be extraordinary and lighting them up can make them stand out from the rest. Backlighting acts like the cherry on top to the solid surface sundae and is a perfect finishing touch. The right type of lighting will make the architecture attract attention, illuminate details, and add dimension to the project.

How do you get the ‘WOW’ factor across in your next solid surface project? Backlighting. Solid surface designs can be extraordinary and lighting them up can make them stand out from the rest. Backlighting acts like the cherry on top to the solid surface sundae and is a perfect finishing touch. The right type of lighting will make the architecture attract attention, illuminate details, and add dimension to the project.